Many customers inquire about the inner workings of hydraulic press brakes, wondering, "How does a hydraulic press brake work?" Hydraulic press brakes operate by utilizing hydraulic pressure to exert force on a punch, which bends sheet metal against a die.

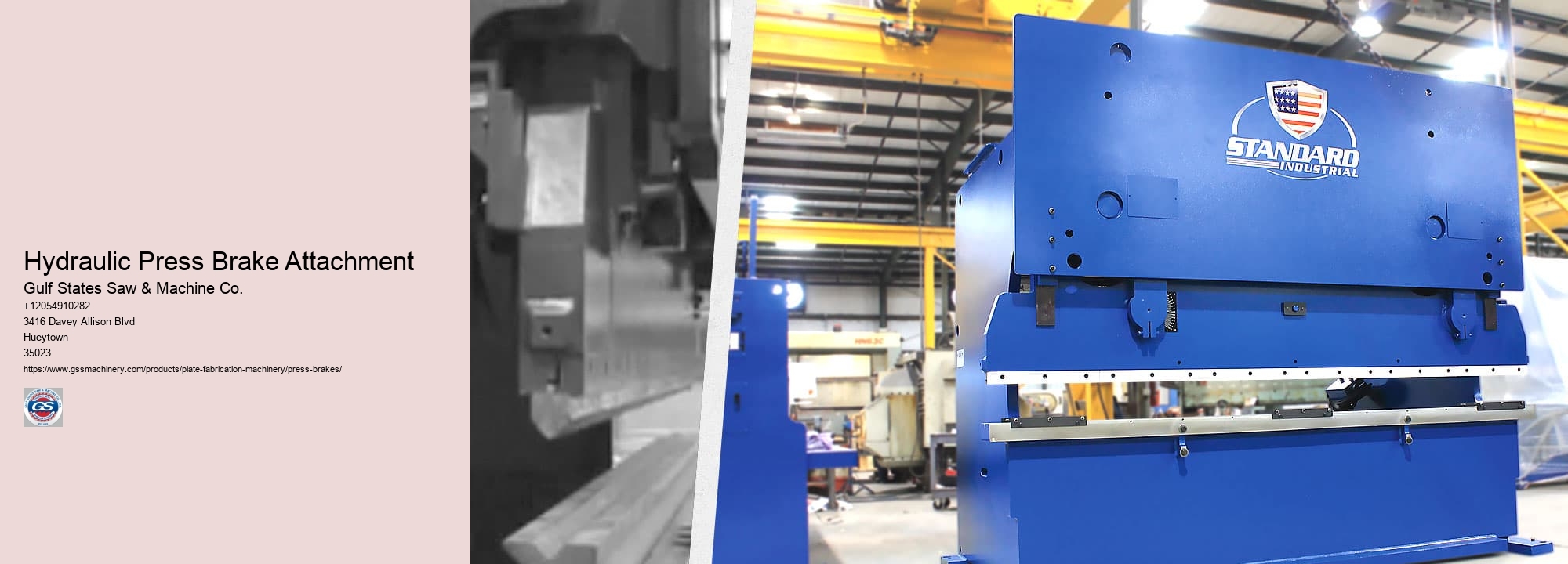

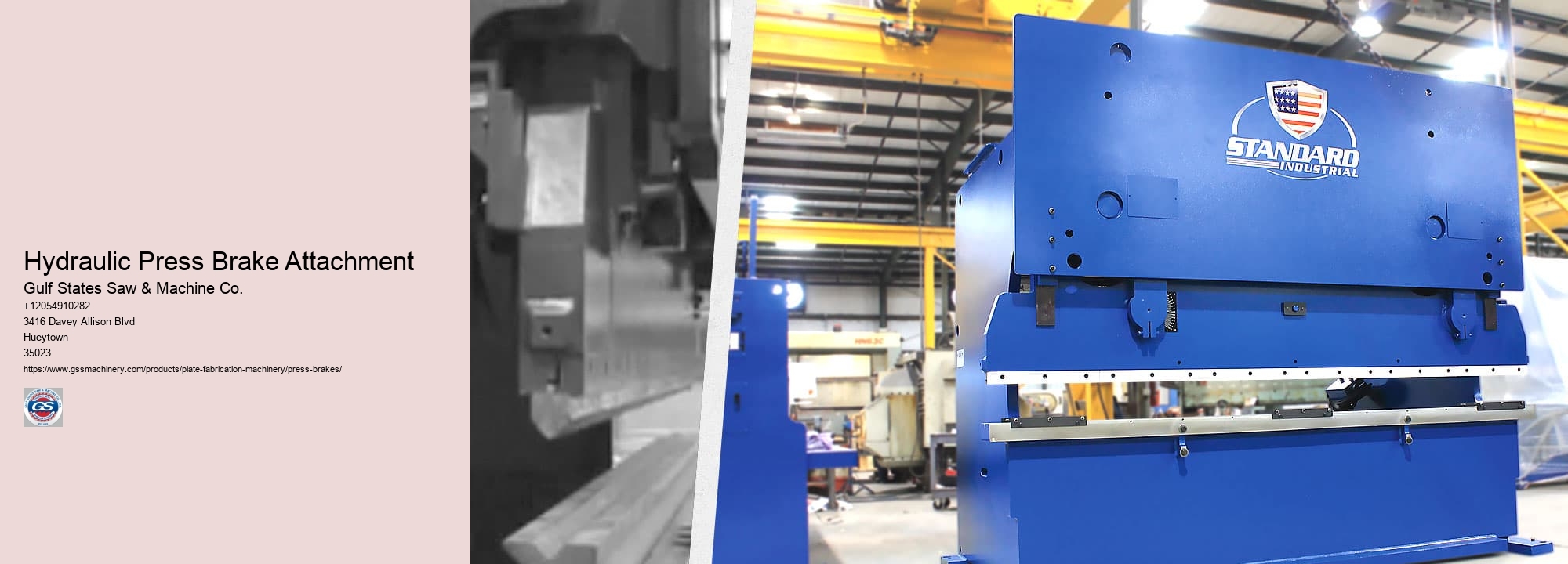

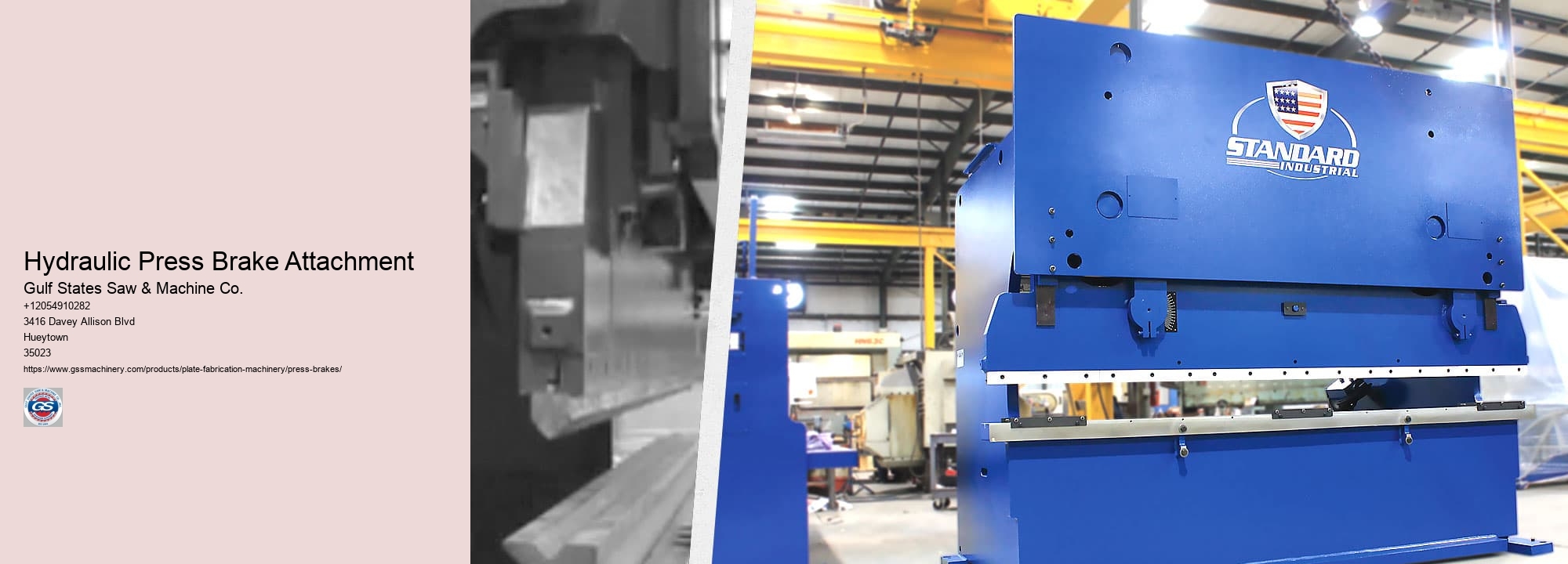

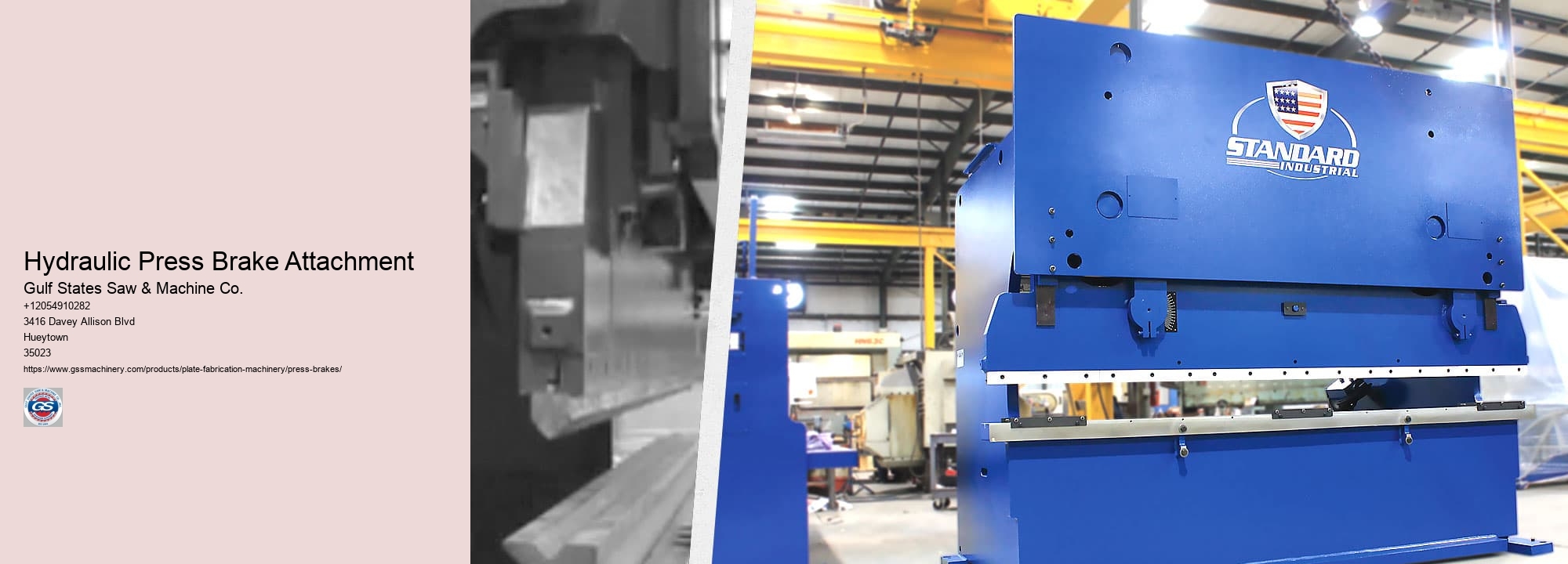

At Gulf States Saw & Machine Co., we prioritize precision and reliability in our hydraulic press brakes. Experience precise metal bending capabilities with Hydraulic Press Brakes These powerful machines utilize hydraulic pressure to shape and bend sheet metal with efficiency and accuracy. Ideal for industries such as manufacturing, fabrication, and engineering, hydraulic press brakes offer versatile solutions for producing high-quality metal components and structures.. That's why we partner with reputable brands like Nokia Brakes to offer high-quality machines known for their exceptional performance. With our hydraulic press brakes, you can expect consistent results and increased productivity in your manufacturing processes.

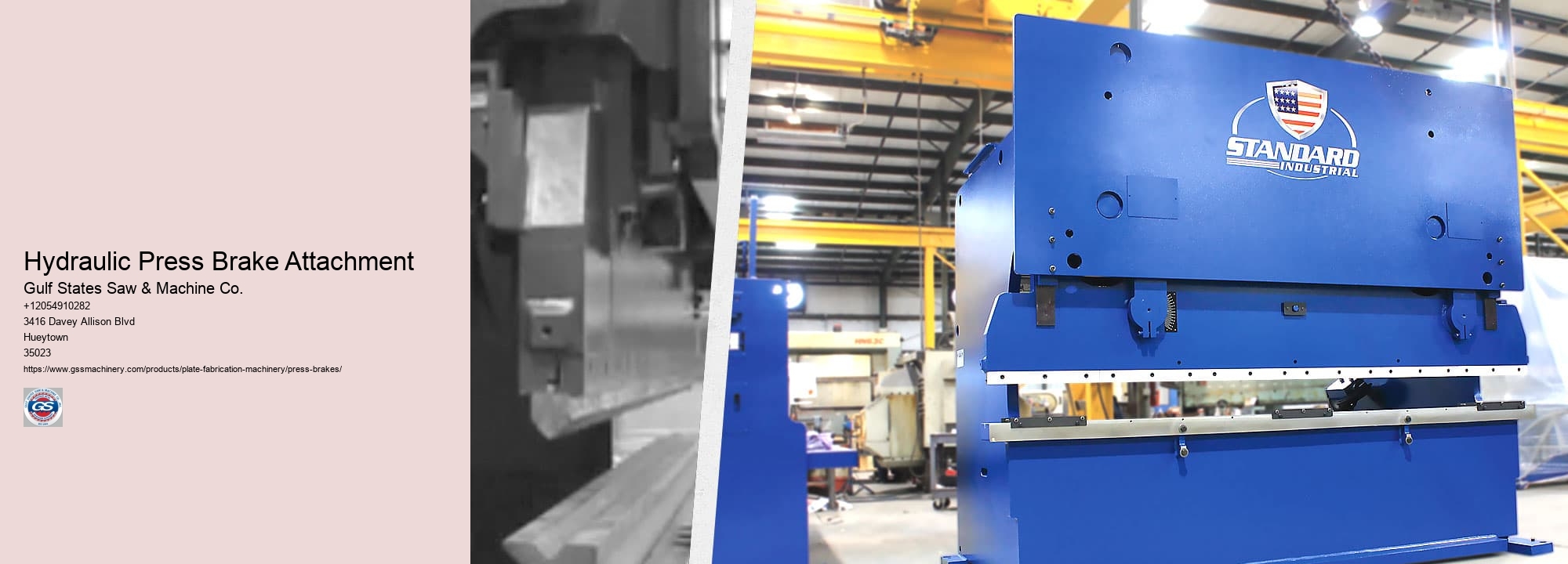

In addition to our wide selection of hydraulic press brakes, we also provide a range of accessories and attachments to enhance machine capabilities. Whether you need hydraulic press brake dies or specialized tooling kits, we have the equipment necessary to optimize your workflow and streamline operations.

Whether you're in need of a new hydraulic press brake or require maintenance and repair services for your existing machine, Gulf States Saw & Machine Co. is here to assist you. Our team is committed to providing tailored solutions that meet your specific needs and exceed your expectations. Automation Contact us today to explore our hydraulic press brake offerings and discover how we can support your business.

Gulf States Saw & Machine Co. stands as a beacon of excellence in providing top-of-the-line hydraulic press brakes meticulously engineered to meet the rigorous demands of industrial applications. With our extensive inventory boasting both new and used options, we ensure that every client finds the perfect hydraulic press brake tailored to their production needs. From precision CNC hydraulic press brakes to versatile manual models, we offer a comprehensive range to cater to various preferences and budgets.

Maintenance is the cornerstone of ensuring optimal performance and longevity for hydraulic press brakes, and our dedicated team of technicians is committed to delivering top-notch service. With our expertise in hydraulic press brake maintenance, including thorough inspections, meticulous lubrication, and timely repairs, we strive to keep your equipment operating at peak efficiency. Our hydraulic press brake troubleshooting services are designed to swiftly diagnose and resolve any issues, minimizing downtime and maximizing productivity.

Clients often inquire about the mechanics behind hydraulic press brakes, asking, "How does a hydraulic press brake work?" Hydraulic press brakes function by utilizing hydraulic pressure to exert force on a punch, which bends sheet metal against a die. This precise bending process enables accurate fabrication of metal components, making hydraulic press brakes indispensable tools across a wide array of industries.

At Gulf States Saw & Machine Co., we place a premium on precision and reliability in our hydraulic press brakes. That's why we collaborate with reputable brands like Nokia Brakes to offer high-quality machines renowned for their exceptional performance. With our hydraulic press brakes, you can trust in consistent results and enhanced productivity in your manufacturing operations.

In addition to our extensive range of hydraulic press brakes, we provide an assortment of accessories and attachments designed to augment machine capabilities.

Whether you're seeking a new hydraulic press brake or require maintenance and repair services for your existing equipment, Gulf States Saw & Machine Co. is your trusted partner. We're dedicated to delivering tailored solutions that meet your unique requirements and surpass your expectations. Reach out to us today to explore our hydraulic press brake offerings and experience the difference we can make for your business.

Gulf States Saw & Machine Co. Process is renowned for its commitment to excellence in providing top-of-the-line hydraulic press brakes meticulously designed to meet the diverse needs of industrial applications. With our extensive inventory featuring both new and used options, we ensure that every customer finds the ideal hydraulic press brake tailored to their production requirements. From advanced CNC hydraulic press brakes to versatile manual models, we offer a comprehensive selection to accommodate various preferences and budgets.

Maintenance plays a pivotal role in ensuring the longevity and optimal performance of hydraulic press brakes, and our team of expert technicians is dedicated to delivering superior service. With our proficiency in hydraulic press brake maintenance, including thorough inspections, precise lubrication, and prompt repairs, we strive to keep your equipment operating at peak efficiency. Our hydraulic press brake troubleshooting services are designed to swiftly identify and address any issues, minimizing downtime and maximizing productivity.

Many clients are curious about the mechanics behind hydraulic press brakes, often asking, "How does a hydraulic press brake work?" Hydraulic press brakes operate by utilizing hydraulic pressure to exert force on a punch, which bends sheet metal against a die. Manufacturer This precise bending process enables accurate fabrication of metal components, making hydraulic press brakes indispensable tools across various industries.

At Gulf States Saw & Machine Co., we prioritize precision and reliability in our hydraulic press brakes. Operations Equipment That's why we partner with esteemed brands like Nokia Brakes to offer high-quality machines renowned for their exceptional performance. With our hydraulic press brakes, you can count on consistent results and increased productivity in your manufacturing operations.

In addition to our extensive array of hydraulic press brakes, we provide a diverse range of accessories and attachments designed to enhance machine capabilities.

Whether you're in the market for a new hydraulic press brake or require maintenance and repair services for your existing equipment, Gulf States Saw & Machine Co.

Gulf States Saw & Machine Co. prides itself on being a leading provider of high-quality hydraulic press brakes meticulously engineered to cater to the diverse needs of industrial applications. Our expansive inventory encompasses both new and used hydraulic press brakes, ensuring that every customer finds the perfect solution to meet their unique production demands. Whether you're in search of a state-of-the-art CNC hydraulic press brake or a reliable manual model, we offer a comprehensive range of options designed to accommodate various preferences and budgets.

Maintenance is essential for ensuring the longevity and optimal performance of hydraulic press brakes, and our team of seasoned technicians is dedicated to delivering top-notch service. With our expertise in hydraulic press brake maintenance, encompassing thorough inspections, precise lubrication, and prompt repairs, we strive to keep your equipment operating at peak efficiency. Our hydraulic press brake troubleshooting services are tailored to swiftly identify and resolve any issues, minimizing downtime and maximizing productivity.

Clients often inquire about the inner workings of hydraulic press brakes, frequently asking, "How does a hydraulic press brake work?" Hydraulic press brakes function by utilizing hydraulic pressure to exert force on a punch, which bends sheet metal against a die.

At Gulf States Saw & Machine Co., we prioritize precision and reliability in our hydraulic press brakes. That's why we collaborate with reputable brands like Nokia Brakes to offer high-quality machines renowned for their exceptional performance. With our hydraulic press brakes, you can trust in consistent results and enhanced productivity in your manufacturing operations.

In addition to our extensive selection of hydraulic press brakes, we provide a diverse range of accessories and attachments designed to augment machine capabilities. Whether you require hydraulic press brake dies or specialized tooling kits, we offer the resources necessary to optimize your workflow and streamline production processes.

Shaping Pressing BendingCommon problems with hydraulic press brakes include oil leaks, hydraulic cylinder issues, and misalignment of the ram.

Safety measures when operating a hydraulic press brake include wearing appropriate personal protective equipment and following proper operating procedures.

Uniformity and consistency in bending with a hydraulic press brake are achieved through proper machine setup, tooling selection, and operator technique.

Selecting the right hydraulic press brake involves considering factors such as material thickness, bending length, and required tonnage.

Different types of tooling, such as punches and dies, are used to achieve various bending profiles on a hydraulic press brake.